Granite precision parts play a crucial role in the calibration of VMM (Vision Measuring Machine) machines. VMM machines are used for precise and accurate measurements of various components in industries such as automotive, aerospace, and manufacturing. The accuracy and reliability of these measurements are highly dependent on the stability and precision of the machine's components, particularly the granite precision parts.

Granite is a popular choice for precision parts in VMM machines due to its exceptional stability, durability, and resistance to wear and corrosion. These properties make it an ideal material for ensuring the accuracy and reliability of the measurements taken by VMM machines. The use of granite precision parts in VMM machines helps to minimize the effects of external factors such as temperature fluctuations and vibrations, which can otherwise compromise the precision of the measurements.

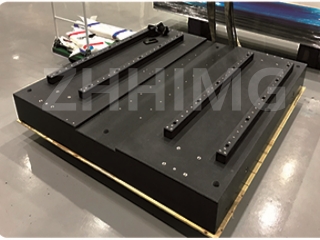

The granite precision parts in VMM machines, such as granite bases and granite stages, provide a stable and rigid foundation for the machine's moving components and measurement systems. This stability is essential for achieving accurate and repeatable measurements, especially when dealing with tight tolerances and complex geometries. The high dimensional stability of granite ensures that the machine maintains its calibration over time, reducing the need for frequent recalibration and maintenance.

Furthermore, the low thermal expansion coefficient of granite helps to minimize the effects of temperature variations on the machine's accuracy, making it suitable for use in diverse industrial environments. The inherent dampening properties of granite also contribute to reducing the impact of vibrations and external disturbances, further enhancing the precision of the measurements.

In conclusion, granite precision parts play a critical role in the calibration of VMM machines by providing the stability, durability, and precision required for accurate measurements. Their use ensures that VMM machines can consistently deliver reliable and high-quality measurement data, making them indispensable tools in various industries where precision and accuracy are paramount. As technology continues to advance, the demand for granite precision parts in VMM machines is expected to grow, further emphasizing their importance in the field of metrology and quality control.

Post time: Jul-02-2024