A CMM (Coordinate Measuring Machine) is a highly accurate and precise measuring device that is commonly used in industries such as aerospace, automotive, and medical. While there are different types of CMMs, one of the most commonly used materials for the base of a CMM is granite. Granite is an excellent material choice as it is rigid, stable, and provides a uniform surface for the CMM to measure from.

However, installing a CMM on a granite base is not enough to guarantee optimal measurement accuracy. There are several factors that need to be considered in order to ensure that the CMM is performing at its best. In this article, we’ll discuss some key factors that need to be considered when installing a CMM on a granite base to optimize measurement accuracy.

1. Temperature Control

Temperature control is one of the most critical factors to be taken into account. Granite has a high coefficient of thermal expansion, which means that it can expand and contract with changes in temperature. Therefore, it is essential to maintain a stable temperature in the room where the CMM is located. Even small temperature fluctuations can cause the granite to expand or contract, which will result in measurement errors. To avoid this, the room should be temperature-controlled, and the CMM should be insulated from any external temperature fluctuations.

2. Vibration Control

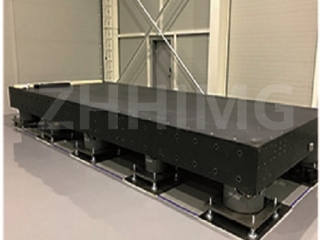

Vibration control is another critical factor to ensure measurement accuracy. Granite is an excellent vibration damper, but it is still susceptible to vibrations from external sources such as other machines, nearby roads, or even foot traffic. These vibrations can cause the granite base to move, resulting in measurement errors. To minimize the impact of external vibrations, the CMM should be placed in a vibration-free location, and any external vibration sources should be isolated or shielded.

3. Leveling

Having a perfectly level granite base is crucial for accurate measurement. When installing a CMM on a granite base, the base should be leveled with high precision. The leveling procedure is critical as even a small deviation can result in measurement errors. Therefore, it is recommended that the leveling is carried out using precision spirit levels and verified using the CMM itself.

4. Installation

Another important consideration is the installation of the CMM on the granite base. The CMM should be installed with great care and precision, to avoid any misalignment or damage. The installation procedure should be carried out by qualified and experienced professionals to ensure that the CMM is installed correctly.

5. Maintenance

Maintaining a CMM is essential to ensure optimal performance and measurement accuracy. Regular maintenance of the machine and the granite base will ensure that the CMM operates at its best. Worn or damaged components need to be replaced promptly, and the granite base needs to be periodically inspected. Regular inspections and maintenance procedures can prevent the need for costly repairs and minimize the impact on measurement accuracy.

Conclusion

In summary, the granite base of a CMM is critical for measurement accuracy. However, installation of a CMM on a granite base is not enough to guarantee optimal measurement accuracy. Several key factors need to be considered, including temperature control, vibration control, leveling, installation, and maintenance. By taking these factors into account, manufacturers can ensure that their CMMs are operating at their best, and accurate measurements are taken on a consistent basis.

Post time: Apr-01-2024