In the world of manufacturing and design, precision is crucial. The ceramic ruler is one of those often overlooked tools that plays a vital role in ensuring accuracy. These rulers are more than just ordinary measuring tools; they are essential tools for quality control in various industries such as woodworking, metalworking, and textiles.

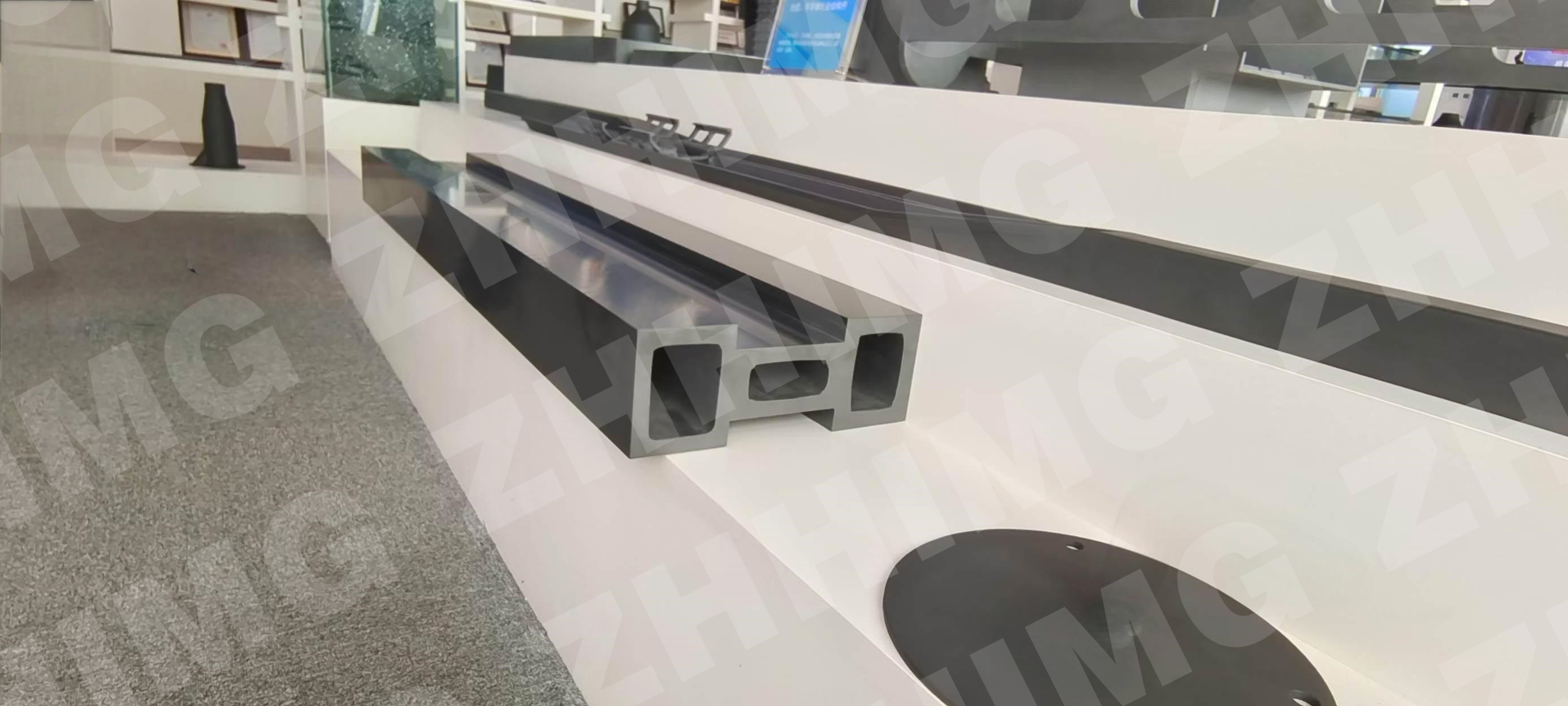

Ceramic rulers are preferred for their durability and resistance to wear and tear. Unlike traditional metal or plastic rulers, ceramic rulers maintain their straightness and accuracy over time, even under rigorous use. This feature is crucial in the quality control process, as even the slightest deviation can lead to major errors in production. Ceramic's non-porous surface also ensures the ruler remains clean and free of contaminants, which is crucial when measuring materials that require a high degree of cleanliness.

Another significant advantage of ceramic rulers is their thermal stability. In environments with frequent temperature fluctuations, ceramic rulers will not expand or contract like metal rulers. This stability ensures consistent measurement results, which is crucial to maintaining quality standards. Additionally, the ceramic ruler's smooth surface allows the marking tool to glide easily, providing clean and precise lines that are essential for accurate measurements.

Additionally, ceramic rulers are often designed with clear and easy-to-read markings to improve usability. This clarity reduces the risk of misunderstandings during quality control, ensuring that all measurements are accurate.

In conclusion, ceramic ruler is an indispensable tool in quality control. Their durability, thermal stability and precision make them ideal for maintaining high manufacturing and design standards. Investing in a quality ceramic ruler is a step toward excellence in any production process.

Post time: Dec-18-2024