For precision engraving, choosing a CNC base is critical for best results. Granite CNC bases are one of the most popular choices among professionals. But why should you consider this material for your engraving needs? Here are a few compelling reasons.

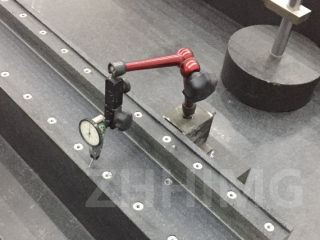

First, granite is known for its exceptional stability. Unlike other materials, granite will not bend or warp over time, ensuring your CNC machine maintains its accuracy. This stability is crucial for engraving, as even the slightest deviation can cause imperfections in the final product. The granite base provides a solid foundation that minimizes vibration, resulting in cleaner, more precise engravings.

Another significant advantage of granite CNC bases is their durability. Granite is a natural stone that can withstand heavy use and resist wear and tear. This long life means you don’t have to worry about frequent replacements or repairs, making it an affordable option in the long run. Additionally, granite resists temperature fluctuations, which helps maintain consistent carving quality.

Granite also has excellent thermal conductivity, helping to dissipate the heat generated during the carving process. This feature is especially important for high-speed operations as it prevents overheating and potential damage to the machine and engraving material.

In addition, the aesthetics of the granite CNC base cannot be ignored. Its natural beauty adds a professional touch to your workspace, making it ideal for businesses focused on functionality and appearance.

All in all, choosing a granite CNC base for your engraving needs is a decision that can significantly improve the quality and efficiency of your work. Granite's stability, durability, thermal properties, and aesthetics make it an ideal choice for any carving professional.

Post time: Dec-20-2024