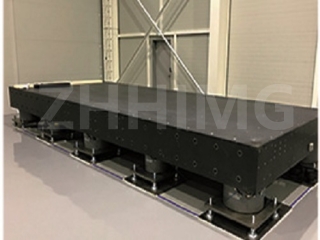

Precision granite is a popular choice for LCD panel inspection devices due to its numerous benefits over other materials. One material commonly used for this purpose is metal, but here are some reasons why granite can be a better option.

1. Stability and Durability

Granite is known for its stability and durability, which are crucial factors for any precision measurement device. It can withstand the wear and tear of daily use and maintain its accuracy over time. On the other hand, metal can have slight variations in its structure, which can affect the accuracy of measurements.

2. Non-Magnetic Properties

Granite is non-magnetic, which makes it ideal for use in electronic devices. Metal, on the other hand, can be magnetic, which can interfere with electronic components.

3. Heat Resistance

Granite has excellent heat resistance compared to metals, which can expand or contract depending on temperatures. This feature is essential for precision measurement devices as even slight variations in temperature can affect the accuracy of measurements.

4. Anti-Vibration Properties

Granite has excellent anti-vibration properties and can absorb shock, minimizing the effect of vibrations on any precision measurement device. Metal can vibrate, causing inaccurate readings.

5. Aesthetic Appeal

Granite is an aesthetically pleasing material that can add to the overall design of inspection devices. Additionally, granite is available in various colors and patterns, making it customizable to suit specific needs.

In conclusion, when it comes to precision granite for LCD panel inspection devices, granite is a superior choice to metal due to its stability, durability, non-magnetic properties, heat resistance, anti-vibration properties, and aesthetic appeal. These features ensure accurate and reliable measurements, making it the go-to material for precision measurement devices.

Post time: Oct-23-2023