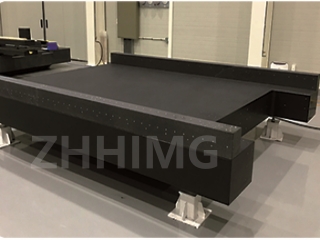

XYZT precision gantry movement platform adopts granite components, which has many special requirements in the installation and debugging process. Compared with the installation process of ordinary material components, it is necessary to give extra control to the key links in order to give full play to its high-precision performance advantages.

Foundation support and level adjustment

Ordinary material components have relatively broad requirements for foundation support, while granite components need more solid and flat foundation support because of their high density and brittle texture. Before installation, ensure that the bearing capacity of the installation ground or foundation platform is at least 2-3 times that of the total weight of the equipment, and ensure that the flatness error of the foundation is controlled within ±0.1mm/m by using a high-precision level. During the installation process, professional wedge iron and adjusting bolts are used to fine-adjust the levelness of the platform, so that the horizontal deviation of the XYZT platform does not exceed ±0.05mm/m in any direction. This link is crucial, a slight deviation, granite components in long-term use may be due to local uneven force cracks, affecting the accuracy and stability of the platform.

Handling and positioning

Granite components are heavy and fragile, and should be handled with great care. Different from the ordinary material can be simple lifting, handling granite components must use professional lifting equipment, equipped with soft protective pads to prevent collision. In the positioning process, the positioning error of the platform is controlled within ±0.02mm by using high-precision measuring instruments such as laser rangefinder and total station. Compared with the relatively loose positioning accuracy requirements of ordinary material components installation, the accurate positioning of granite components is directly related to the accuracy of subsequent movement, if the positioning is not accurate, it will lead to uneven stress of the guide rail, lead screw and other transmission components, aggravate wear, reduce the service life of the platform and movement accuracy.

Connect and fix

The connection methods of ordinary material components are diverse and the fault tolerance rate is high, while the connection of granite components needs special consideration. When using a special binder or mechanical connection, it is necessary to operate in strict accordance with the process requirements. When adhesives are used, the coating thickness and uniformity must be precisely controlled to ensure bond strength while avoiding stress concentration caused by inconsistent binder thicknesses. The mechanical connection should choose the appropriate bolts and nuts, control the tightening torque, and prevent excessive tightening resulting in cracking of granite. After the connection is completed, the ultrasonic flaw detector and other equipment are used to detect the connection parts to ensure that there are no defects, and to ensure the stability of the overall structure of the platform and the ability to maintain accuracy.

Electrical and control system commissioning

In the electrical and control system debugging stage, the sensitivity of ordinary material components to the fine tuning of electrical parameters is relatively low, and the high-precision characteristics of granite components require more accurate electrical parameter matching. It is necessary to use professional debugging software to finely calibrate the motor speed, torque and other parameters, so that the acceleration and deceleration process of the platform movement is smooth and smooth, and the positioning is rapid and accurate. Real-time monitoring of the platform motion status through high-precision sensors, feedback to the control system for optimization and adjustment, to ensure that the platform can be accurately executed under the movement instructions at the micron or even nanometer level, giving full play to the high-precision potential of granite components.

Post time: Apr-14-2025