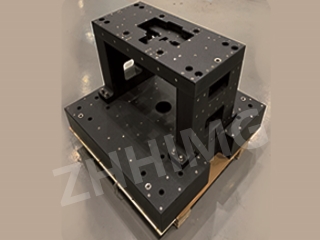

In the high-precision field of aerospace parts processing, XYZT precision gantry movement platform has become a key manufacturing force with its excellent performance, especially its granite components, which inject strong power for the improvement of processing accuracy.

As the core component of aero engine blade, the requirement of machining accuracy is almost strict. The shape of the blade is complex, and its surface accuracy directly affects the combustion efficiency, thrust and fuel economy of the engine. XYZT precision gantry movement platform is equipped with granite components, showing extraordinary strength in blade processing. Granite has a very low coefficient of thermal expansion, which can effectively resist the size fluctuations caused by temperature changes during processing to ensure that the platform is always in a stable state. This makes the positioning accuracy of the platform up to ±0.01mm when milling and grinding the blade surface. With this precision, complex surfaces in design drawings can be accurately reproduced, and blade profile errors can be controlled within a very small range, meeting the machining requirements of aero-engine blades for high-precision surfaces.

In aerospace parts processing, in addition to blades, the manufacturing of key components such as aircraft landing gear also relies on high-precision machining. XYZT precision gantry movement platform granite components with high rigidity and excellent vibration resistance. When drilling and milling the landing gear parts, it can effectively isolate the external vibration interference, prevent the tool from jitter during the cutting process, ensure that the hole accuracy can reach ±0.02mm, and the slot width accuracy error is controlled within ±0.03mm, which greatly improves the manufacturing accuracy and quality of the landing gear and other parts. Provide a solid guarantee for the safety of aircraft take-off and landing.

In short, XYZT precision gantry movement platform granite components, in the field of aerospace parts processing to complete complex surface processing and various key parts manufacturing tasks with high precision, to help the aerospace industry continue to break through the technical bottleneck, to a higher level.

Post time: Apr-14-2025