Blog

-

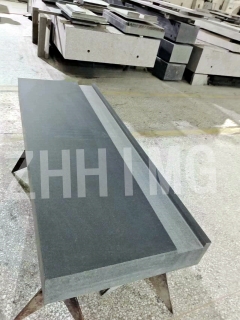

The advantages of black granite guideways product

Black granite guideways are a popular product used in a wide variety of industries due to their many advantages. These guideways are made from high-quality black granite and have many features that ensure their reliability, precision, and longevity. In this article, we w...Read more -

How to use black granite guideways ?

Black granite guideways are a type of linear guide system that is primarily used in precision machinery. These guideways provide excellent accuracy and rigidity, which makes them ideal for applications that require precise and repetitive motion, such as measuring instruments, machine tools, CNC m...Read more -

What is a black granite guideways ?

Black granite guideways are a specialized type of linear motion system used in precision manufacturing processes. These guideways are made from high-quality, precision-cut granite that has been specially treated and finished to provide a perfectly flat, hard, and durable...Read more -

The advantages and disadvantages of Granite precision platform

Granite precision platforms have been used in various industries for a long time. They are known for their incredible durability, high-level accuracy and excellent stability. Granite itself is made of natural stone, which makes it a popular material for precision surface...Read more -

How to repair the appearance of the damaged Granite precision platform and recalibrate the accuracy?

Granite precision platforms are highly important in industries such as aerospace, automotive, and mechanical engineering. These platforms are used to measure and inspect parts with high accuracy. However, due to wear and tear or accidents, it is possible for the granite ...Read more -

What are the requirements of Granite precision platform product on the working environment and how to maintain the working environment?

Granite precision platforms are widely used in various fields including manufacturing, research and development, and quality control. These platforms are known for their high accuracy and stability, which makes them an ideal choice for precise measurements and testing. H...Read more -

How to assemble, test and calibrate Granite precision platform products

Granite precision platform products are commonly used in various industries such as aerospace, automobile, and mold manufacturing. These platforms are known for their high precision and reliability which make it necessary to have a proper assembling, testing, and calibra...Read more -

The application areas of Granite precision platform products

Granite Precision Platform products are highly sought-after for their high accuracy, durability, and versatility. They are widely used in various industries and applications globally. These products are made from robust materials such as granite, stainless steel, and alu...Read more -

The defects of Granite precision platform product

The Granite precision platform is a highly sought-after product in the field of manufacturing, particularly in industries that require ultra-high precision in their operations. It is known for its exceptional stability, accuracy, and durability, making it a preferred cho...Read more -

What is the best way to keep a Granite precision platform clean?

Granite precision platforms are used in a variety of applications, from construction to fabrication and precision measurement. They are quite durable, strong, and dense, which makes them an ideal choice for various industrial purposes. However, with constant usage, they ...Read more -

Why choose granite instead of metal for Granite precision platform products

Granite is a natural stone that has been used for centuries in construction and as a material for precision platforms. It is a popular choice for precision machining applications due to its excellent stability, durability, and resistance to wear and tear. When compared t...Read more -

How to use and maintain Granite precision platform products

Granite precision platform products are widely used in various industries for a variety of purposes due to their high precision and stability. These products are specifically designed to provide accurate measurements and withstand high loads. To use and maintain Granite ...Read more