Blog

-

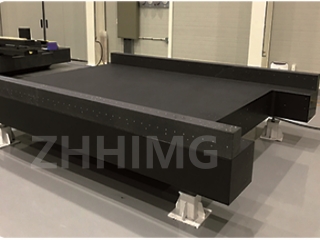

The advantages of precision granite for SEMICONDUCTOR AND SOLAR INDUSTRIES product

Precision granite has become one of the most important materials used in the semiconductor and solar industries. Its unique characteristics, such as high stability, durability, and accuracy, make it an essential component for semiconductor and solar equipment manufacture...Read more -

How to use precision granite for SEMICONDUCTOR AND SOLAR INDUSTRIES ?

Precision granite is a natural stone material that has been used for centuries in various industries, including the semiconductor and solar industries. The semiconductor and solar industries require materials that are highly accurate and precise to ensure that the end pr...Read more -

What is a precision granite for SEMICONDUCTOR AND SOLAR INDUSTRIES ?

A precision granite is a tool used in the semiconductor and solar industries to ensure high accuracy, stability, and precision in measurements and processes involving delicate materials and components. It is made of high-quality granite, known for its exceptional rigidit...Read more -

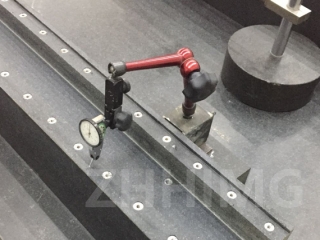

How to repair the appearance of the damaged granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES and recalibrate the accuracy?

Granite machine parts are commonly used in the automobile and aerospace industries due to their high stability and precision. However, over time, these parts may become damaged due to wear and tear, environmental factors, or accidents. It is important to repair the appea...Read more -

What are the requirements of granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES product on the working environment and how to maintain the working environment?

Granite is a widely used material in the manufacturing industry, especially in the production of machine parts for the automobile and aerospace sectors. These two industries require high precision, durability, and reliability in their equipment, making granite a suitable...Read more -

The advantages and disadvantages of granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES

Granite is a natural stone that is highly valued for its durability, strength, and aesthetic appeal. While commonly used in construction projects, it has also become a popular material choice for machine parts in the automobile and aerospace industries. In this article, ...Read more -

The application areas of granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES products

Granite has been widely used in various industrial applications due to its exceptional properties such as high strength, excellent dimensional stability, and resistance to wear, corrosion, and thermal deformation. The automotive and aerospace industries are not exception...Read more -

the defects of granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES product

Granite is a natural stone that is widely used in the manufacturing of machine parts for the automobile and aerospace industries. Although this material is considered to be very durable and reliable, it can still have some defects that can affect its quality and performa...Read more -

What is the best way to keep a granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES clean?

Keeping granite machine parts clean is essential in ensuring their longevity and optimal performance. This is especially important in the automobile and aerospace industries, where precision and efficiency are paramount. In this article, we will discuss some of the best ...Read more -

Why choose granite instead of metal for granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES products

Granite is a popular choice for machine parts in the automobile and aerospace industries, despite being a non-traditional material for this purpose. The use of granite in manufacturing has been growing in popularity because of its many benefits over other materials like ...Read more -

How to use and maintain granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES products

Granite machine parts are widely used in the manufacturing process of automobile and aerospace industries. These parts are known for their durability, precision, and strength, making them an essential component of the manufacturing process. Proper maintenance and care of...Read more -

the advantages of granite machine parts for AUTOMOBILE AND AEROSPACE INDUSTRIES product

Granite is one of the most widely used natural materials across the globe due to its numerous advantages, including durability, longevity, and resistance to wear and tear. Due to these unique properties, granite has become a preferred choice for manufacturing machine parts, particularly for the a...Read more